AMERICA

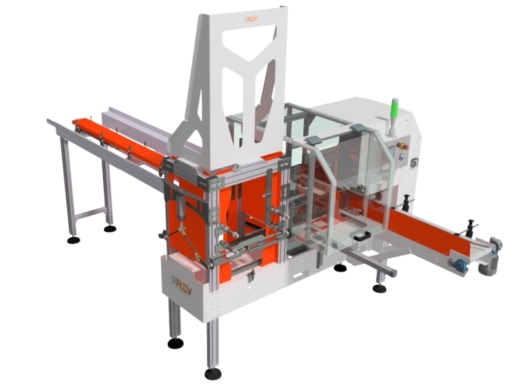

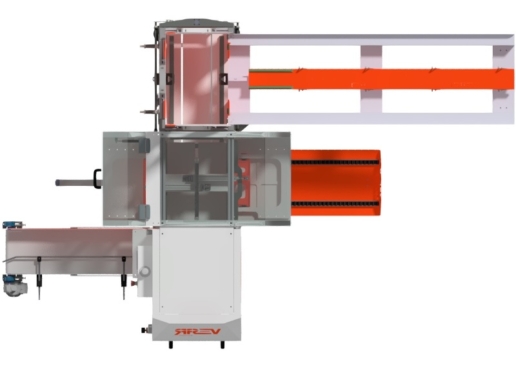

FILLER OF OPEN CRATES WITH MULTIFORMAT PUNNETS

ALLOWING QUICK FORMAT CHANGES

EASY TO USE

EXTREMELY FAST

WIDELY CUSTOMISABLE

- Automatic machine for filling open crates with punnets.

- 60% faster with respect to traditional machines, thus, ideal for high-productivity flowpack and topseal lines.

- It processes both crates in plastic (IFCO, CPR, EPS, CHEP, etc.) and in cardboard, provided that their upper part is completely open.

- It works with any type of punnet, both in plastic and cardboard.

- Easily programmable with different recipes, thus, it can manage an amount of punnets variable according to the format, on more layers too.

- Suitable for processing delicate products.

IDEAL FOR:

strawberries, small fruits, peaches, nectarines, kiwifruits, apricots, plums, tomatoes, avocados, cherries, pears, grapes, etc. (all products usually contained in punnets).

Do you need further information about our machines?

TECHNICAL FEATURES

- 4.3” colour touch-screen control panel

- New intuitive R-Touch graphic interface with production statistics

- Workable crates: 600×400 mm, height up to 190 mm, open type only

- Workable packages: clamshell; in flowpack; with lid; netted; open; cartons with wings

- Punnet formats: from 4 to 15 punnets per layer; 1 or 2 layers

- Approximate production: 60-75 punnets/min.

OPTIONS

- Full-crate-outfeed roller conveyor

- Different types of empty-crate feeders

- Different mounting configurations, according to the plant

- Different shims for reducing the punnet dropping

- Kit of crate-extraction sucker

- Easy Remote teleassistance

- Integration into SCADA systems

- 4.0 interconnection